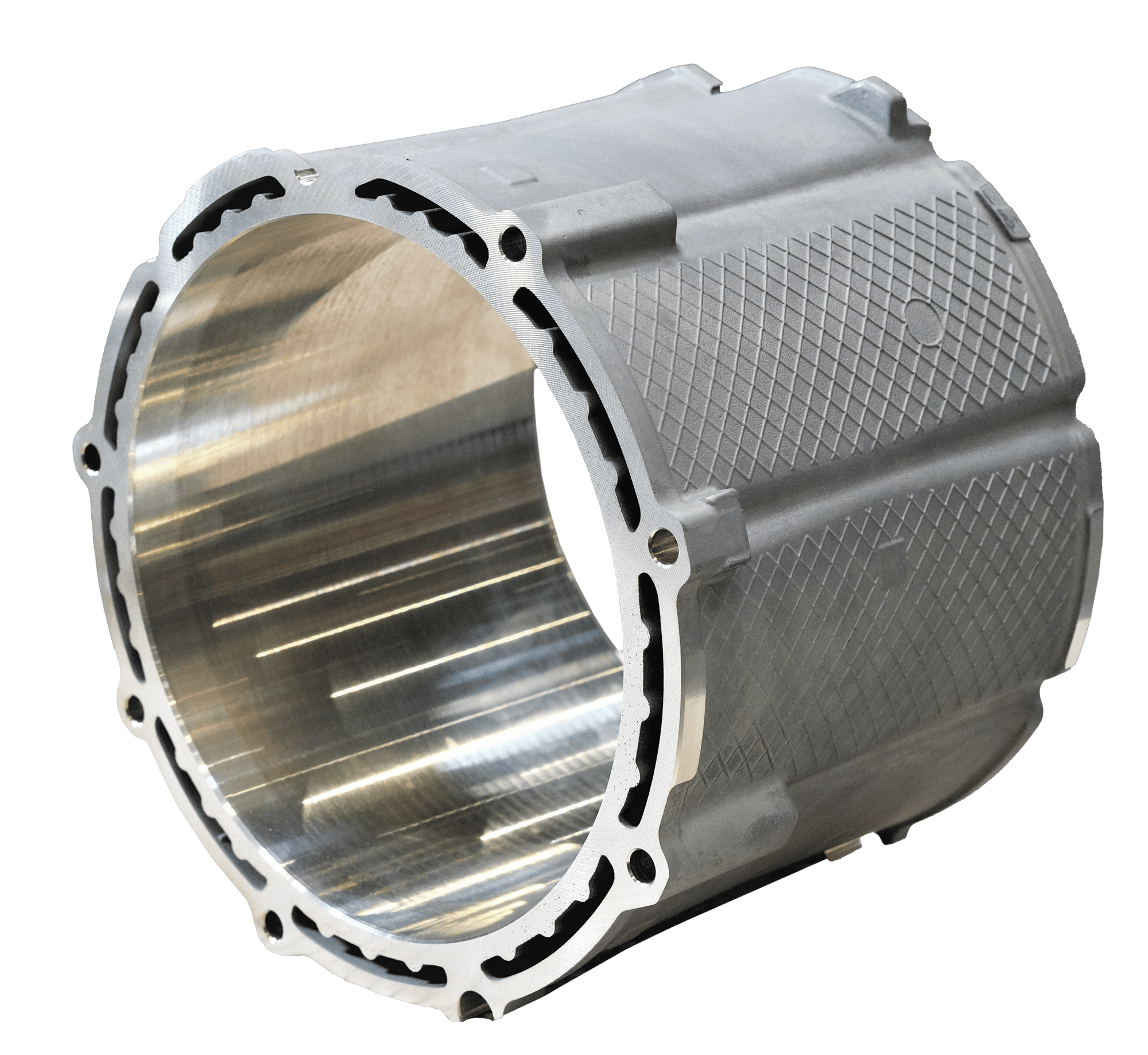

Aluminium Motor Housing for

VW ID. 3 / ID.4 / ID.5

Process stability and minimisation of rejects through the use of

advanced metal treatment technology

Motor Housing case study

The combination of the MTS Melt Treatment Station with SMARTT degassing control and automated dosing of NUCLEANT 1582 grain

refining fluxes delivered a 10% reduction in the scrap rate.

SMARTT working principle

Learn how the SMARTT technology is optimising your process

Brochure

Products for chemical melt treatment of aluminium alloys

Brochure

SMARTT - An innovative process control for rotary degassing of aluminium alloys

SMARTT - Defined hydrogen levels after aluminium rotary degassing

The production of Aluminium castings globally is dominated by the automotive industry. To ensure that the correct casting quality is achieved, a more effective and technically sound melt treatment is essential, followed by a well-designed and controlled pouring practice. Automotive industry requests process reproducibility and so any melt treatment adopted must be capable of achieving consistent levels of cleanliness and hydrogen control. Many quality management systems also require a 100 % record of production data, so again a sophisticated melt treatment with data storage capabilities becomes more attractive.

Day 1

Monday 12th June

No video selected

Select a video type in the sidebar.