HOLLOTEX EG RUNNER ST and STELEX Optiflow3D

Gating system components for steel casting and 3D Filters

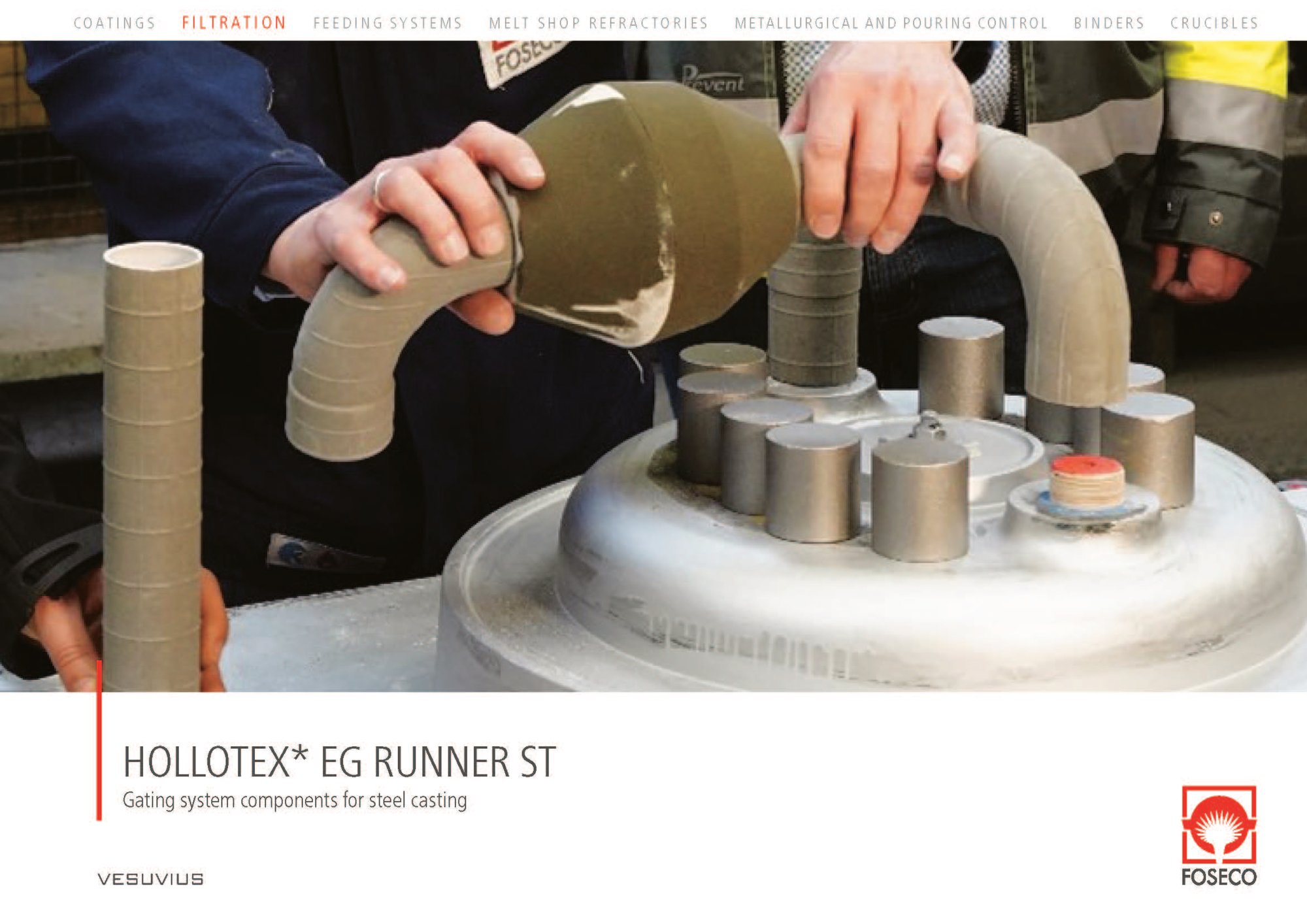

HOLLOTEX EG Runner ST tubes: A lightweight alternative to clay ceramic gating systems, now also available for steel casting

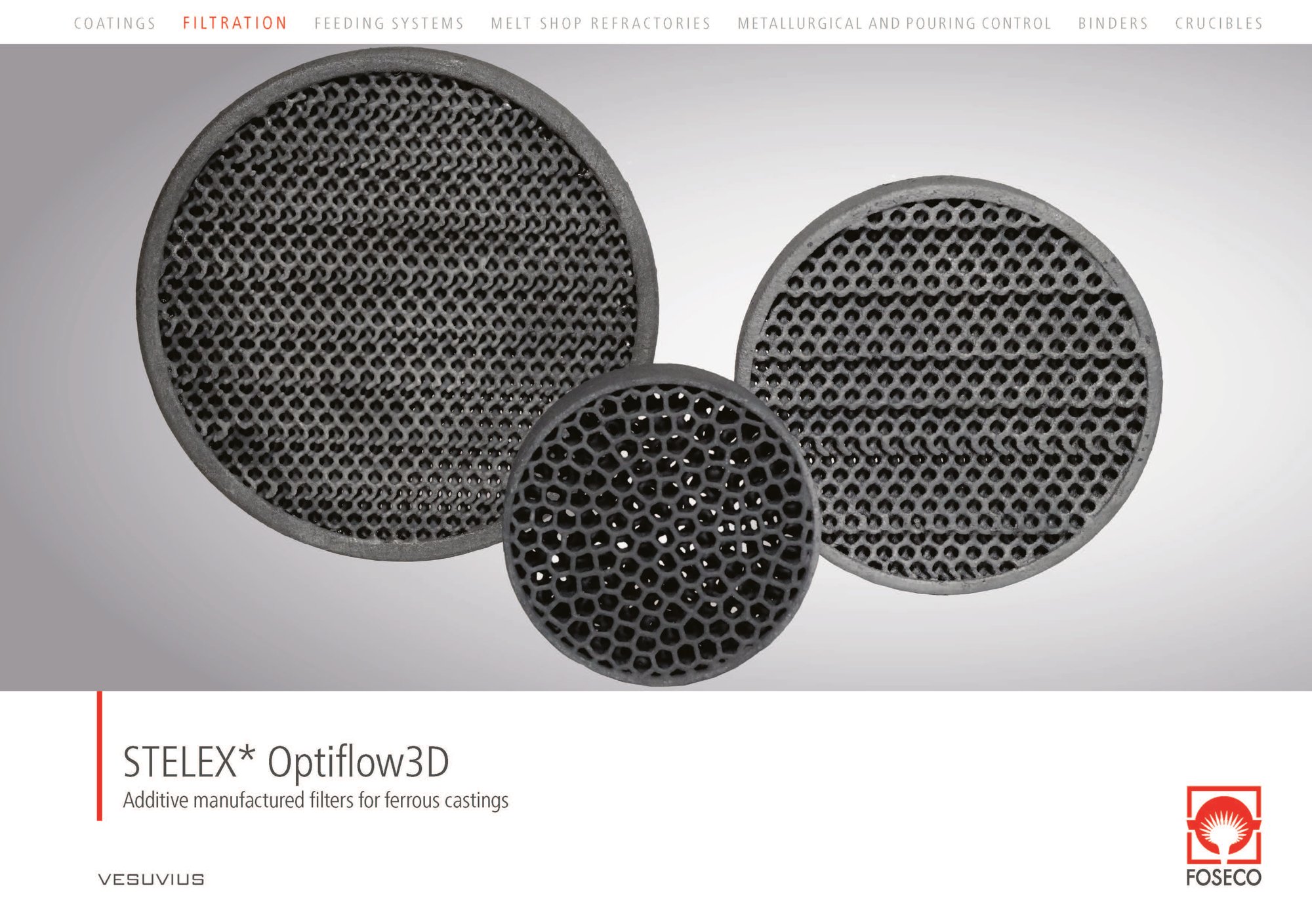

STELEX Optiflow 3D filters offer both filtration efficiency and consistent flow rates. The filters have a higher capacity than foam alternatives and facilitiate the filtering of larger castings.

Case study

Case study of a steel planet carrier for a small gear box, showing how the application of HOLLOTEX EG Runner ST and STELEX Optiflow 3D printed filters led to improved surface finish, faster handling and less wear in sand operating machines.

The incorporation of Additive Manufacturing Technology (3D) in casting filtration, providing optimised efficiency and customization

Ceramic foam filters have become the leading choice for metal filtration in casting since the 1980s. They are extensively used across various alloys and casting technologies, providing cleaner castings with improved properties. Over the years, our understanding of filter application has advanced significantly, and guidelines have been developed to ensure their durability. Despite their limitations in pore size and design flexibility, ceramic foam filters outperform other filter types in terms of filtration efficiency and turbulence control. The emergence of additive manufacturing, particularly 3D printing, offers new opportunities for customised filter designs with precise pore sizes and structures, further optimising casting filtration.

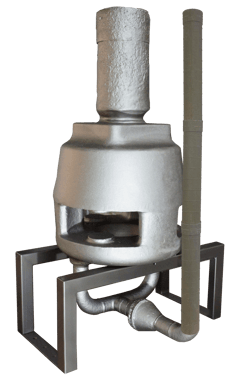

HOLLOTEX* EG RUNNER ST - The lightweight alternative to ceramic gating systems, now also available for steel casting!

HOLLOTEX EG Runner, introduced in 2009, revolutionised the construction of gating systems for hand-moulded iron castings. It eliminated the need for ceramic components and gained popularity in the European and American iron casting markets. However, it had limitations in withstanding high pouring temperatures used in steel casting.

To address this, HOLLOTEX EG Runner ST was developed with an optimized formulation and a refractory coating. Additionally, the shape of the components was modified to improve the flow distribution of molten metal.

Brochure

HOLLOTEX EG RUNNER ST

Brochure

STELEX Optiflow3D

Day 1

Monday 12th June

No video selected

Select a video type in the sidebar.