VAPEX FOSFLOW

Quick interchangeable nozzles for steel foundry

applications

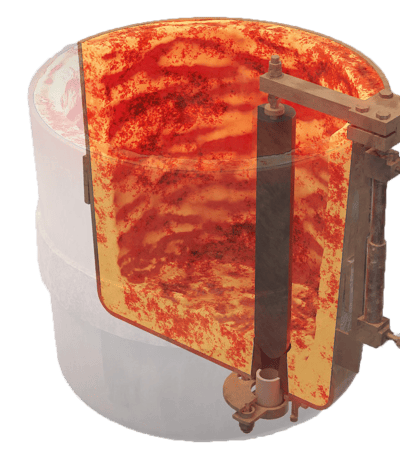

VAPEX FOSFLOW system enables foundries to rapidly change nozzle diameter, even in a full ladle without the need to remove and replace the nozzle and stopper.

VAPEX FOSFLOW case study

Fast pouring nozzle change while ladle is still hot

VAPEX FOSFLOW case study

Quick nozzle change for bottom pour ladles with less refractory work

VAPEX FOSFLOW animation

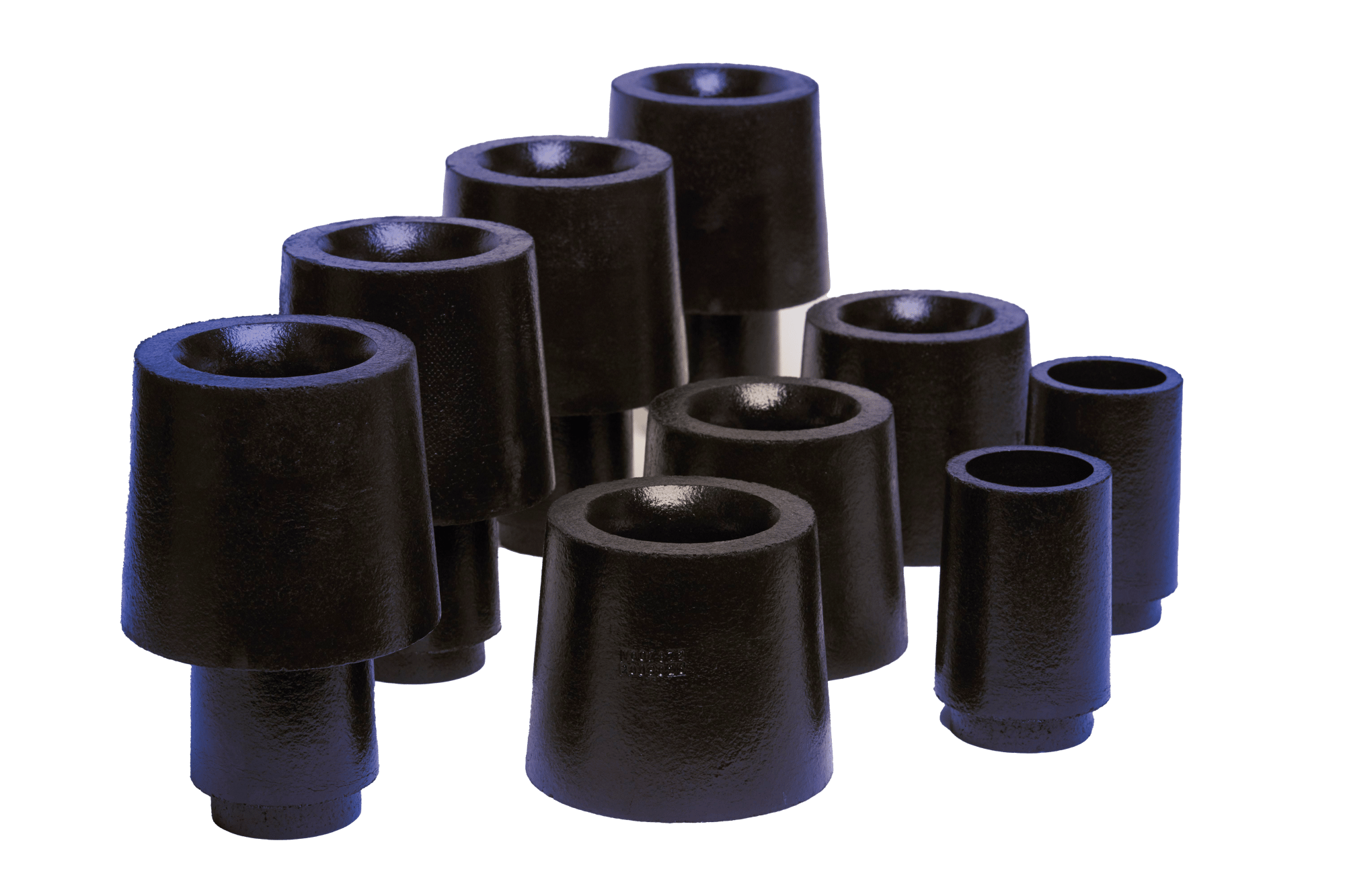

Nozzle technologies for iron and steel foundries

This article will give you an overview of actual nozzle technologies for iron autopour and steel bottom pour applications. Looking at steel foundries in particular, lip pouring by Teapot ladles or when using bottom pour technologies, a one shot, low alumina nozzle are widespread technologies. Over the years, new long life or quick change solutions have been developed. Cross-Bore and Multi Life nozzle solutions have been mentioned in previous articles (see below). We now also introduce our new VAPEX FosFlow nozzle system. Finally we include our newly developed Zirconia nozzles, which are used for the production of metal powders for additive manufacturing using 3D printers to create complex steel structures.

Day 1

Monday 12th June

No video selected

Select a video type in the sidebar.