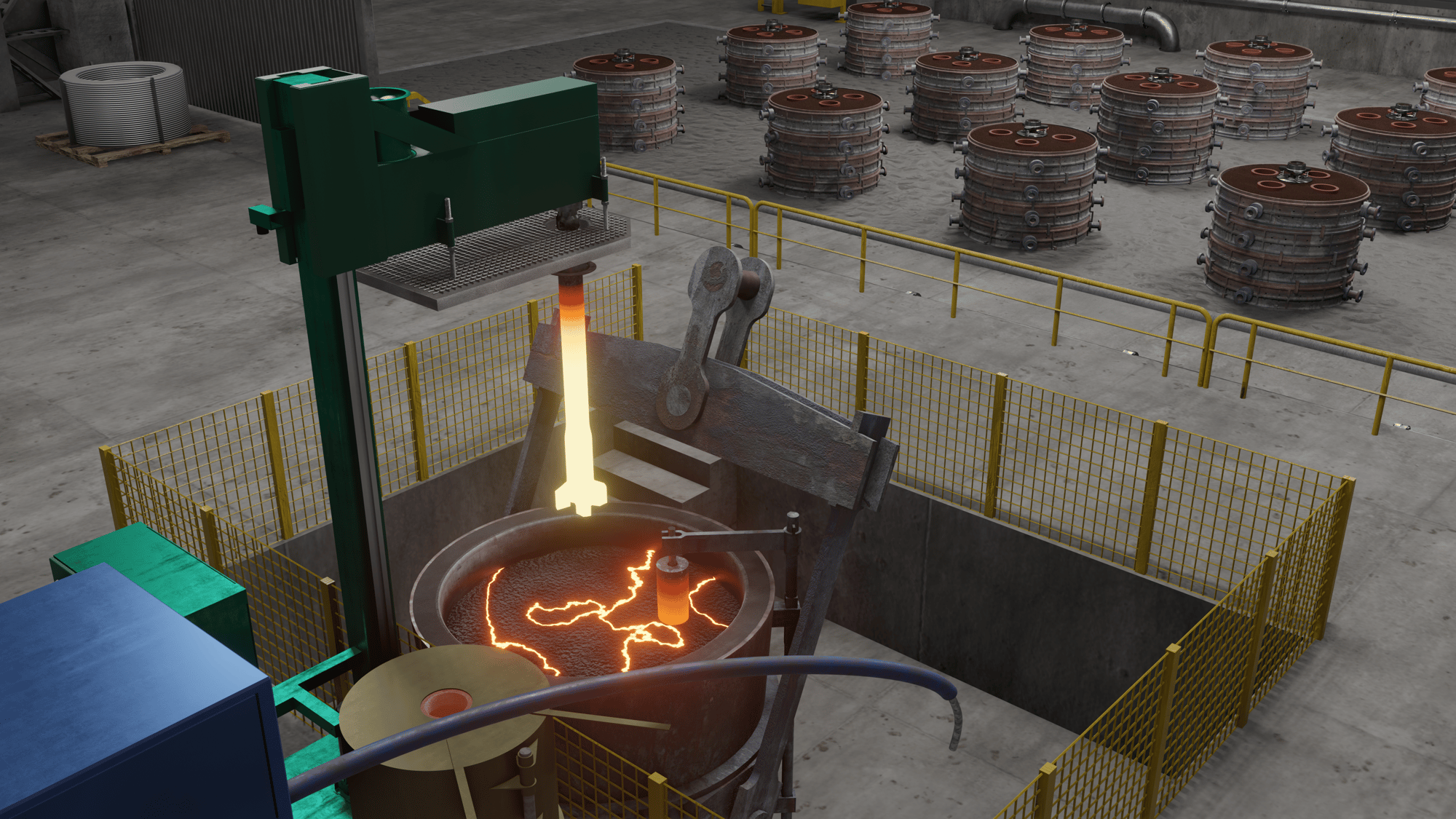

ROTOCLENE process

Rotary treatment of molten metal at the pouring ladle

ROTOCLENE is a new process for producing the highest quality, inclusion-free steel for casting. The process uses rotary action to stir the metal and disperse fine argon bubbles through the melt. These bubbles are highly effective at catching any inclusions and bi-films, floating them to the melt surface, where they are trapped in the slag layer. The rotary action also homogenises melt temperature and eliminates cold spots. This allows the steel to be poured at lower temperatures, reducing shrinkage and promoting finer microstructures. This is all possible in a standard bottom pour ladle.

Mining truck spindle case study

Castings quality improvement and rework reduction by 30%

.jpg?width=1280&height=854&name=DSC08290_(1280_x_1024).jpg)

Piston case study

Casting quality improvement by reducing pouring temperature by 70°C

ROTOCLENE animation

Clean steel castings at ultralow pouring temperatures for high performance applications using the innovative rotoclene process

This article describes a new technique for improving the quality of Steel melts in the ladle prior to pouring. The Process involves a rotary treatment process that stirs the metal in the ladle whilst passing a curtain of fine Argon bubbles through it. Together with flux and wire additions the process leads to effective inclusion removal, homogenized temperature, modification and desulfurization. The technique allows the steel to be cast at much lower temperatures even semi liquid, resulting in fine cast microstructures and reduced defects.

Day 1

Monday 12th June

No video selected

Select a video type in the sidebar.